Machinery

PRESSES

Heavy presses

• 8 hydraulic presses with tonnage 200t - 1200t

• 11 mechanical presses with tonnage 250t - 500t.

Light presses

• 13 mechanical presses from 40 to 160 tons

LASER (2kW, 6kW and 10kW)

LASER

Laser cutting machining parameters BySprint Fiber3015 Fiber Laser BYSTRONIC type Fiber 2000, 6000 and 10000:

• Cutting accuracy - depends on material dimensions

• Cutting Capacity - 3048 mm / 1524 mm,

Maximum thickness:

• Constructional steel - 25 mm,

• Stainless steel - 30 mm,

• Aluminum - 30 mm,

• Brass - 15 mm,

• Copper - 12 mm.

BENDING

We have two CNC mandrel bender. The modern design allows a very simple way to set the relevant parameters and precision hydraulic drive system provides the ability to bend pipes in a wide range of sizes.

Processing parameters:

• The maximum pipe diameter - 65 mm,

• Bending accuracy - 0.1 mm,

• The maximum wall thickness - 3 mm,

• The maximum bending angle - 190 °

PRESS BRAKE

We have a modern, hydraulic press brake RICO numerically controlled company, with a maximum pressure of 160 tons. The current sets of prisms and stamps, which allow you to have different sheet metal bending with complex shapes. The machine performs bending elements with an accuracy of 0.05 mm, with 100% repeatability and allows you to correct the angle through bend.

Processing parameters:

• Accuracy of ± 0.05 mm bending,

• The length of the bend - 3100 mm,

• Maximum force - 160 tons

PAINT SHOP

Specifications paint lines:

• Conveyor length - 290 m

• Maximum dimensions of parts: 2000mm height, szer.350mm, length 900 mm

The line consists of:

• Tunnel prepare the surface to allow the use of modern methods to ensure better protection against corrosion

• Drying Oven

• A large booth with the application of Nordson (28 guns)

• Furnace controlled polymerization automatically ensures proper distribution throughout the oven temperature to guarantee the correct polymerization of powder in the full temperature range.

• Details of the suspension are transferred conveyor with a length of 290 m

All units are located in the hall separated from the rest of the production, which ensures excellent surface painting.

CUT LINES

Line No. 1

• strip thickness - 1mm

• width - 1000mm

• Maximum coil weight - 8 tons.

Line No. 2

• the strip thickness from 0.5 to 2.0 mm

• max belt width 450 mm.

• Maximum coil weight - 3 tons.

Automatic tape cutter:

Maximum size of crossed [cut at 90 ⁰]

• 250mm circular cross-section

• 250x200 rectangular cross-section

- Automatic feeding system

- Cut at an angle in the range - 0-45 degrees

- The accuracy of a single application- 0.2 mm

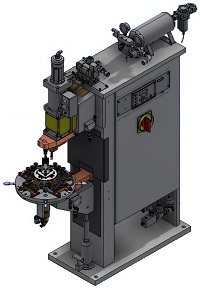

SPOT WELDING

Stationary spot-projection resistance welding machine.

Nominal power at P50%-100kVA.

Possibility of welding low carbon steel, galvanized steel, stainless steel and aluminium.

Spot welding machine is equipped in microprocessor weld driver TE-550.